Minigun

USINFO | 2013-11-21 16:16

| Machine Gun, High Rate, 7.62mm, M134 | |

Dillon Aero's M134D-H (H for Hybrid) combines the titanium and skeletonized parts that were engineered for use in the M134D-T minigun with the steel housing of the previous M134D. |

|

| Type | Gatling-type machine gun |

| Place of origin | United States |

| Service history | |

| In service | 1963–present |

| Used by | See Users below |

| Production history | |

| Designer | General Electric |

| Designed | 1960 |

| Manufacturer | General Electric, Garwood Industries , Dillon Aero, DeGroat Tactical Armaments, McNally Industries LLC |

| Produced | 1962–present |

| Variants | See Design and variants below |

| Specifications | |

| Weight | 85 pounds [47.8 lightweight mod.] |

| Length | 801.6 mm |

| Barrel length | 558.8 mm |

|

|

|

| Cartridge | 7.62×51mm NATO |

| Caliber | 7.62 mm (0.308 in) |

| Action | Electrically driven rotary breech |

| Rate of fire | Variable, 2,000–6,000 rpm |

| Muzzle velocity | 2,800 ft/sec (853 m/s) |

| Maximum range | 3,280 ft (1,000 m, 1,093 yd) |

| Feed system | Disintegrating cartridge beltorlinkless feed; dependent on installation [500-5,000 round belt] |

| Sights | Dependent on installation; no fixed sights |

The M134 Minigun is a 7.62x51 mm NATO, six-barreled machine gun with a high rate of fire (2,000 to 6,000 rounds per minute). It features Gatling-style rotating barrels with an external power source, normally an electric motor. The "Mini" of the name is in comparison to designs that use a similar firing mechanism but larger shells, such as General Electric's earlier 20-millimeter M61 Vulcan, and "gun" for a caliber size smaller than that of a cannon, typically 20 mm and higher.

"Minigun" refers to a specific model of weapon that General Electric originally produced, but the term "minigun" has popularly come to refer to any externally powered Gatling gun of rifle caliber. The term is also used to refer to guns of similar rates of fire and configuration regardless of power source and caliber.

History

Background: electrically driven Gatling gun

The ancestor to the modern minigun was made in the 1860s. Richard Jordan Gatling replaced the hand cranked mechanism of a rifle-caliber Gatling gunwith an electric motor, a relatively new invention at the time. Even after Gatling slowed down the mechanism, the new electric-powered Gatling gun had a theoretical rate of fire of 3,000 rounds per minute, roughly three times the rate of a typical modern, single-barreled machine gun. Gatling's electric-powered design received U.S. Patent #502,185 on July 25, 1893. Despite Gatling's improvements, the Gatling gun fell into disuse after cheaper, lighter-weight, recoil and gas operated machine guns were invented; Gatling himself went bankrupt.Background: electrically driven Gatling gun

During World War I, several German companies were working on externally powered guns for use in aircraft. Of those, the best-known today is perhaps the Fokker-Leimberger, an externally powered 12 barrel Gatling gun in the 7.92x57mm Mauser round, claimed to be capable of firing over 7,000 rpm, but suffering from frequent cartridge-case ruptures due to its "nutcracker", rotary split-breech design, which is fairly different from that of a Gatling. None of these German guns went into production during the war, although a competing Siemens prototype (possibly using a different action) which was tried on the Western Front scored a victory in aerial combat. The British also experimented with this type of split-breech during the 1950s, but they were also unsuccessful.

A couple of externally powered Gatling gun designs were patented although never used. During WW2, the blowback-operated Neal submachine gun that used rotating barrels firing .22LR rounds at a rate of 3000rpm was also developed as a weapon for US forces, but it was felt that existing submachine guns fulfilled its role.

Minigun: 1960s–Vietnam

In the 1960s, the United States Armed Forces began exploring modern variants of the electric-powered, rotating barrel Gatling gun-style weapons for use in the Vietnam War. American forces in the Vietnam War, which used helicopters as one of the primary means of transporting soldiers and equipment through the dense jungle, found that the thin-skinned helicopters were very vulnerable to small arms fire and rocket-propelled grenade (RPG) attacks when they slowed down to land. Although helicopters had mounted single-barrel machine guns, using them to repel attackers hidden in the dense jungle foliage often led to barrels overheating or cartridge jams.

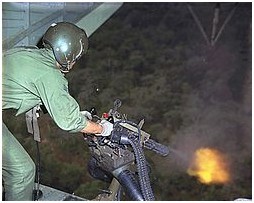

A U.S. Air Force rotary-wing crewman fires a minigun during the Vietnam War.

In order to develop a weapon with a more reliable, higher rate of fire, General Electric designers scaled down the rotating-barrel 20 mm M61 Vulcan cannon for7.62×51 mm NATO ammunition. The resulting weapon, designated M134 and known popularly as the Minigun, could fire up to 4,000 rounds per minute without overheating. The gun was originally specified to fire at 6,000 rpm, but this was later lowered to 4,000 rpm.The Minigun was mounted on OH-6 Cayuse and OH-58 Kiowa side pods, in the turret and wing pods on AH-1 Cobra attack helicopters, on door, pylon and pod mounts on UH-1 "Huey" Iroquois transport helicopters.

Several larger aircraft were outfitted with miniguns specifically for close air support: the A-37 Dragonfly with an internal gun and with pods on winghardpoints, and the A-1 Skyraider also with pods on wing hardpoints. Other famous gunship airplanes were the AC-47 Spooky, the AC-119 gunship, and the AC-130 gunship.

Share this page